Type: Rice Bran Oil Refinery Processing Line

Productive Capacity: 2-2000 Tons per day

Rice Bran Oil Processing Material: Crude Rice Bran Oil

Major Equipment of Rice Bran Oil Refinery: Crude Oil Tank, Decolorizing Mixing Tank, Deodorizing Tank, Crystallization Tower, Maturing Tank etc.

Application:

Generally speaking, Rice bran oil refining plant is to obtain refined rice bran oil well

In rice bran oil refining workshop, the crude rice bran oil become refined oil by special oil processing to get rid of impurities, wax, gums, FFA, pigment and odors. All in all, rice bran oil refining process consists of continuous dephosphorization and degumming section, physical deacidification and deodorization section, continuous dehydration section, bleaching and Filtration Section, crystallization and maturing section, dewaxing section and electrical control system.

Rice Bran Oil Refining Process:

1) Firstly, to pump crude rice bran oil into oil refining tank with heat conduction oil, and the temperature will reach about 70°C-80°C in one hour, then add acid or alkali to separate rice bran oil according to the acid value. After one hour’s processing and 4-6 hours deposit, then to convey soap stock to storage tank;

2) Secondly, to pump refined rice bran oil into decoloring tank. When it up to 90°C-110°C after one hour’s heating, then to add clay into tank for 20 min’s processing, and to separate clay and oil with filter;

3) Finally, to put decolorizing oil into deodorization tank with vacuum pump. Heating process with steam is for odor removal. After filtering, you will get final rice bran oil products.

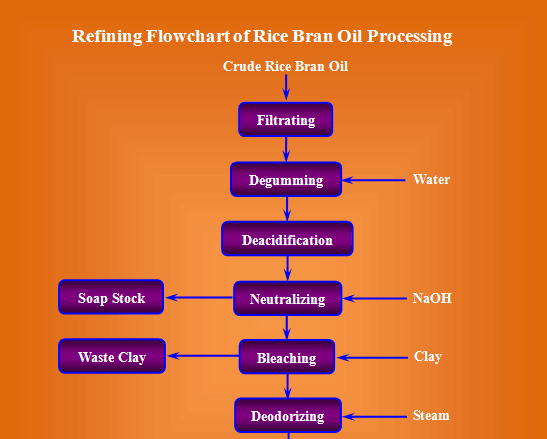

There is the rice bran oil refining process flow chart for you as follows: Crude rice bran oil →Filtrating →Degumming & Dephosphorization →Deacidification →Neutralizing →Bleaching →Deodorization →Refined oil.

Refining Section: To P-acid de-gumming, alkali refining de-acid and water rinsing.

Decoloring Section: To remove off pigments, bleaching oils and grease dehydrate.

Deodorizing Section: To remove off the odor components in rice bran oil.

Dewax: To remove off the wax in the rice bran oil, in order to get the high quality oil.

Heat-transfer Oil Stove: To supply each device needing heat energy, temperature to reach above 280°C.

Steam Generator: To produce the needing steam for de-odoring and distillation.

Vacuum Pump: To supply needing vacuum for dehydrate, de-color, de-odor. Vacuum degree can reach above 755mm Hg.

Press Filter: To filter clay and get clear rice bran oil.

Air Compressor: Blow dry bleached clay, blow empty the leftover oil in the press filter.

Craft Features of Huatai Rice Bran Oil Refining Plant:

1) Continuous alkali refining shortens the contact time between oil and lye, reduces grease oil saponification, lower refining consumption and improves efficiency;

2) Decolorization adopts technology of combing of premixing and steam mixing bleaching. Moreover, it can improve the bleaching efficiency, save consumption of bleaching clay, and it is simple and convenient to operate; and the negative pressure state avoids oxygen in the air from contacting with hot oil, thereby ensuring oil product quality, and inhibiting acid value to rise again and lowering peroxide value;

3) Deodorization adopts the new type continuous deodorization equipment, it is applicable for plant oil deacidification and deodorization of oils high acid value and low-resin content. In this way, the actual production proves its most obvious advantages are strong deacidification ability, excellent hot bleaching effect, high refining rate (increase for 0.4/AV), steam economization, good oil quality and the like;

4) Henan Huatai Rice Bran Oil Production Machinery has multiple heat exchanges, which not only makes full use of the heat energy system, and effectively reduces steam consumption, but also has the advantages of adjustable oil production capacities, flexible operation, high automatic degree, environment sanitation and other advantages.

Specifications of Huatai Small-sized Rice Bran Oil Refining Unit: 2-10T/D

Product Features:

1) It is for intermittent refining, not only has all functions of large and medium-sized intermittent edible oil refining equipment, but also is better than the large and medium-sized cooking oil refining equipment;

2) It is combined into whole set, what’s more, it can provide heat source by itself with electric control, as well as light weight and low power consumption;

3) It covers a small area, and is easy to operate.

Certifications:

Henan Huatai Cereals and Oils Machinery Co., Ltd. has been committed to the production and research and development of grain and oil machinery for 37+ years. It has mature production and manufacturing processes and skilled technical workers for edible oil processing, and is committed to providing customers with high-quality, cost-effective cooking oil equipment. The products are sold to more than a dozen countries and are well received by domestic and foreign customers!

Huatai Oil Machinery specializes in the production of oil equipment, mainly cooking oil press machine, vegetable oil refining equipment, edible oil extraction machine, complete edible oil production lines, etc. From raw material pretreatment to finished oil filling, the equipment models are complete and the quality is good. A variety of specifications and models meet the needs of different customers.

Also, we provide customized services for edible oil plants, from edible oil factory design drawings, equipment location drawings, process flow charts, equipment production and installation, technical operation training and after-sales services, to helps customers solve oil technology problems. Huatai Oil Machinery provides guarantees for the smooth production of the cooking oil plant.

All in all, to consult and purchase rice bran oil processing machine, you can go to Henan Huatai Cereals and Oils Machinery Co., Ltd. We will send you the complete fetures and specifications of the equipment. Please contact us for the price of Rice Bran Oil Processing Equipment.