Type: Complete Set of Rice Bran Oil Production Line, Rice Bran Oil Mill Project Cost, Rice Bran Oil Machine

Processing Capacity: 10-200 Tons per day

Raw Material: Rice Bran

Rice Bran Oil Factory Processing Flow: Rice bran oil is extracted from the germ and inner husk (bran) of rice. It is a valuable domestic oil resource in many countries1. The production line of rice bran oil involves a series of processes including pretreatment, extraction, and refining.

Rice Bran Oil Pretreatment Plant: Rice Bran-tips Separation Section; Rice Bran Softening And Condition Section; Rice Bran Extrusion Machine.

Main Equipment of Rice Bran Oil Production Line: Magnetic Selector, Rice Bran-tips Separation Sieve, Elevator, Softening Conditioner, Cooker etc.

Rice bran oil pretreatment process flow and parameters:

Rice bran → magnetic separation → rice bran and tips separation → rice bran softening and contdition → rice bran expansion → drying and cooling → to the rice bran oil solvent extraction plant

1. Technical index for puffing Rice Bran Oil Pretreatment Process:

(1) Moisture of puffed rice bran: 7-8%

(2) Color of Puffed Rice Bran: Normal

2. Consume of puffing pretreatment plant:

(1) Electric consume per ton matarial: 35 kw.h

(2) Steam consuming per ton matarial: 200kg

(3) Water consume per ton material: 50kg

Rice Bran Oil Solvent Extraction Machinery: Solvent Extraction Section; Desolventizing And Toasting Section; Evaporation Section; Condensation Syetem.

Main Equipment: Rotocel/Loop/Towline Extractor, Desolventizer Toaster, Mixed Oil Evaporator etc.

Rice bran oil solvent extraction process flow and parameters:

Rice bran cake → oil extraction system → wet meal desolvation system → mixed oil treatment system → solvent recovery system → crude rice bran oil

1. Technical index of Rice Bran Oil Solvent Extraction Plant:

(1) Residual Oil in Cake: Main Equipments: ≤1.5%

(2) Color of Cake: Normal

(3) Residual solvent in crude oil: ≤300ppm

(4) Volatile substance in crude oil: ≤ 0.2%

(5) Color of crude oil: No smell, clean when temperature higher than 80¡æ

2. 20-200T/D rice bran oil solvent extraction equipment process indicators:

(1) Solvent consumption: 2.5kg/t raw material

(2) Steam consumption£» 250-300kg/t raw material

(3) Residual oil content of meal: ≤0.5-1.5%

(4) Power consumption: 12-19kwh/t material

(5) Water vomsumption: 0.5-1.5 CBM/ raw material

(6) Residual solvent of meal: ≤500ppm (qualified explosion test)

Rice Bran Oil Refining Plant: Physical Deacidification And Deodorization Section; Rice Bran Oil Continuous Dewatering Section; Rice Bran Oil Decolorization And Filtering Section; Rice Bran Oil Crystallization And Maturing Section; Rice Bran Oil Dewaxing Section; Electric Control System.

Main Equipment: Filter Equipment, Deacidification Tower, Crystallization & Maturing Tank, Deodorization Tower, Crude Oil Tank, Decolorizing Tank etc.

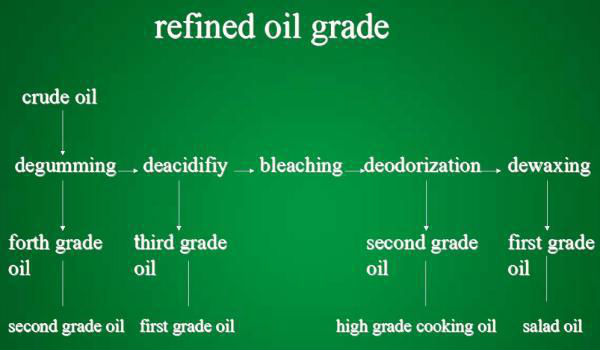

rice bran oil refining process

Rice bran oil refining process flow and parameters:

Crude rice bran oil → degumming → deacidification → decolorization → deodorization → dewaxing → refined rice bran oil

1. Quality requirements of crude oil:

(1) Moisture and volatile matter of crude oil: ≤0.25%

(2) Impurity content of crude oil: ≤0.2%

(3) Acid value of crude oil (mgKOH/g): ≤7

2. Product quality index:

(1) Transparency: Clear and transparent

(2) Smell and taste: No strabge smell

(3) Color (Lovibond colorimeter 133.4 slots): ≤R1 Y10

(4) Moisture and volatile mater: ≤0.10%

(5) Impurities content: ≤0.10%

(6) Acid value (mgKOH/g): ≤0.12

(7) Peroxide value (mmol/kg): ≤3

3. Consumption of Rice Bran Oil Refining Plant:

(1) Steam consume: ≤380kg/t oil

(2) Electric consume: ≤33kw.h/t oil

(3) Water consume: 200kg/T oil (include soft water)

(4) Phosphoric acid consume: 3kg/t oil

(5) Alkali consume: Acid value x 1kg/t oil

(6) Blanching vlay consume: 40-60kg/t oil

(7) Residual oil on waste belching clay consume: <24%

(8) Circulating cooling water consume: 400 m³/h

Specification of Small-scale Edible Oil Refining Unit: 2-10T/D

Product Features:

1) It is for intermittent refining, and has all functions of large and medium-sized intermittent Rice Bran Oil Refining Equipment, also better than the large and medium-sized refining equipment;

2) Combined into whole set, it can provide heat source by itself with electric control, light weight and low power consumption;

3) It covers a small area, and easy to operate.

Overseas Business Offices and Projects:

30T/D Rice Bran Oil Making Project in Bangladesh

100T/D Rice Bran Oil Factory/Mill Plant in Bangladesh

Cambodia 30T/D Rice Bran Oil Making Project built by Huatai Oil Machinery

Also we have the business office in Bangladesh, Nigeria, Uzbekistan, Ukraine, Kazakhstan, etc. Welcome to visit us, we will provide the latest rice bran oil machine price.

Certifications:

Henan Huatai Cereals and Oils Machinery Co., Ltd. has been committed to the production and research and development of grain and oil machinery for 37+ years. It has mature production and manufacturing processes and skilled technical workers for edible oil processing, and is committed to providing customers with high-quality, cost-effective cooking oil equipment. The products are sold to more than a dozen countries and are well received by domestic and foreign customers!

Huatai Oil Machinery specializes in the production of oil equipment, mainly cooking oil press machine, vegetable oil refining equipment, edible oil extraction machine, complete edible oil production lines, etc. From raw material pretreatment to finished oil filling, the equipment models are complete and the quality is good. A variety of specifications and models meet the needs of different customers.

Also, we provide customized services for edible oil plants, from edible oil factory design drawings, equipment location drawings, process flow charts, equipment production and installation, technical operation training and after-sales services, to helps customers solve oil technology problems. Huatai Oil Machinery provides guarantees for the smooth production of the cooking oil plant.

All in all, to consult and purchase rice bran oil processing machine, you can go to Henan Huatai Cereals and Oils Machinery Co., Ltd. We will send you the complete fetures and specifications of the equipment. Please contact us for the price of Rice Bran Oil Processing Equipment.