Rice bran is the main by-product of rice processing mill, such as per 100kg rice can produce about 5-8kg rice bran. It is also a common kind of oil-bearing material. With the development of rice processing industry and oil extraction technology, setup rice bran oil factory machine is becoming a HOT project with great commercial value to invest in. Rice bran oil making machine is not only oil pressing, but also include oil extraction and oil refining, which is important to produce cooking rice bran oil.

How is Rice Bran Oil Made? How to Start A Rice Bran Oil Extraction Plant?

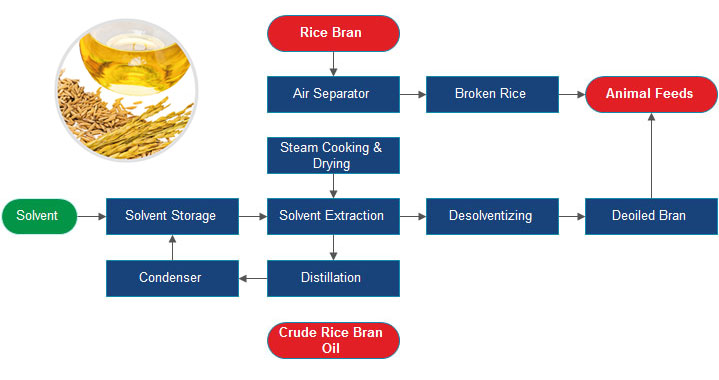

A complete rice bran oil production line generally includes 3 sections: rice bran oil pretreatment section, rice bran oil solvent extraction section, and rice bran oil refining section.

Rice Bran Pretreatment Machine:

Rice bran pre-processing machine generally includes the processes of screening and heating, set for making the rice bran well prepared for oil extraction, just like extraction of other oilseeds.

The purpose of heating is stabilize the rice bran materials. There are two methods of stabilization, chemicals or using heat. Heat method causes the enzymes inside the rice bran to deactivate in 110-130¡æ, which is done by heat injection or extrusive cooking. Stabilization is very crucial to remove the bacteria and enzymes, that cause the rice bran to get spiteful and to lower the fat acid rate.

Huatai Key Technology – Stabilization Treatment Capability

Huatai’s rice bran oil equipment and technology can convert rice bran waste into high-value edible oil and animal feed, increasing rice mill profits by more than 30%.

The problem of rice bran rancidity is a major challenge hindering the entire rice bran oil industry. Fresh rice bran contains highly active lipases, which rapidly decompose oils within hours of milling, leading to a sharp increase in acid value and a significant decrease in oil yield and quality.

Huatai’s rice bran oil equipment’s “stabilization treatment” capability directly addresses this problem, with its core technology focusing on “timeliness” and “efficiency”:

1) Process Route: Typically adopts the “extrusion stabilization” process, which is a widely recognized and efficient technology in the rice bran oil industry.

2) Key Processes:

Immediate Collection and Transportation of Fresh Rice Bran: The system design emphasizes minimizing the time from the rice milling workshop to the rice bran processing section.

Conditioning and Extrusion: Rice bran is processed through an extrusion machine at a specific temperature (usually 110-130℃) and humidity. This process completely inactivates the lipases within tens of seconds, while simultaneously breaking down the rice bran cell walls, facilitating subsequent rice bran oil extraction.

Cooling and Drying: The extruded rice bran particles (called “rice bran meal”) are rapidly cooled to prevent quality degradation due to residual heat, and the moisture content is reduced to a safe storage level.

3) Treatment Effects:

Enzyme inactivation rate > 99%, effectively preventing the rapid increase in acid value.

The treated stabilized rice bran can be safely stored for several months without significant rancidity, making large-scale, intensive production possible.

Rice bran extrusion process also improves the rice bran oil extraction efficiency and crude oil quality in subsequent processes.

The stabilization treatment stage in Huatai’s rice bran oil equipment is not just “one process,” but a crucial technical prerequisite for the successful profitability of the entire rice bran oil project. It ensures the stability of the raw materials, thereby guaranteeing the yield and quality of the final product.

Rice Bran Oil Solvent Extraction Machinery:

Rice Bran Oil Screw Press Machine: Suitable for 1-20ton/day rice bran oil production line.

Rice Bran Oil Solvent Extraction Machine: To achieve higher oil yield and improve production efficiency, solvent is used in most industrial or commercial rice bran oil project. It is ideal choice for medium to large rice bran oil factory. (The capacity can be up to 1000 ton/day).

Extraction by using volatile solvent is the best way for medium and large scale rice bran oil processing mill. Then, the extracted rice bran oil is separated from the solvent through vaporization, the best solvent to use is ethanol. The remaining rice bran waste can be used as a fodder due to its high rate of carbohydrate and protein. There are two outputs in this step: crude rice bran oils, and defatted rice bran meal.

Rice Bran Oil Refining Plant:

Basic rice bran oil refinery: clay compound (dewaxing), phosphatides (degumming), fat acid (saponification), dye (bleaching) and scent (deodorization).

Rice bran oil refining machine is set to remove the majority of free fatty acids and bran wax in crude rice bran oil, and make the oil suitable for different applications such as edible oil, biodiesel oil, food additives, etc. The crude rice bran oil will be degummed by enzymatic method, then deacidified and decolorized by enzymatic method.

In some cases when processing dewaxed oil, de-waxing process is also included in rice bran oil refinery plant. Steam distillation is the last step of edible rice bran oil factory machine. The purpose is to remove any off flavors and residual free fatty acids. In middle-large rice bran oil factory, rice bran oil refining plant is built to improve the quality of final oil.

Conclusion and Recommendations:

1. Technical Reliability: Huatai’s rice bran oil equipment’s stabilization processing capability is the technical cornerstone of the rice bran oil project, effectively addressing the challenge of raw materials being prone to rancidity, thus ensuring stable production and high-quality products. This is a crucial step towards investment success.

2. Economic Feasibility: From an industry perspective, a well-designed and scientifically managed rice bran oil project typically has a static investment payback period of 2-4 years, demonstrating good profitability and attractive potential ROI.

3. Key Recommendations:

In-depth Research: Thorough research must be conducted on the supply (quantity, price, and stability) of rice bran raw materials in the local and surrounding areas, as well as the edible oil/feed market.

Obtain a Precise Rice Bran Oil Processing Solution: Contact us to obtain a detailed rice bran oil process plan and quotation based on your specific needs (scale, product grade, automation level).

Comprehensive Planning: Don’t focus solely on rice bran oil equipment price; plan the entire value chain, including raw material procurement and storage, production management, byproduct sales, and finished oil brand building. Consider cooperating with large rice mills or establishing your own procurement and storage points to secure raw materials.

The rice bran oil industry has market potential based on the concept of healthy edible oil. Choosing a technically sound rice bran oil equipment supplier like Huatai is a good start for project success, but the ultimate return on investment depends more on the overall operation and management capabilities of the project. It is recommended to conduct on-site inspections and detailed financial feasibility studies before making a final decision.

Best Solutions For Your Rice Bran Oil Production Factory:

Huatai Oil Machinery has been committed to the production and research and development of grain and oil machinery for 37+ years. It has mature production and manufacturing processes and skilled technical workers for edible oil processing, and is committed to providing customers with high-quality, cost-effective cooking oil equipment. The products are sold to more than a dozen countries and are well received by domestic and foreign customers!

Huatai Oil Machinery specializes in the production of oil equipment, mainly cooking oil press machine, vegetable oil refining equipment, edible oil extraction machine, complete edible oil production lines, etc. From raw material pretreatment to finished oil filling, the equipment models are complete and the quality is good. A variety of specifications and models meet the needs of different customers.

We also provide customized services for edible oil plants, from edible oil factory design drawings, equipment location drawings, process flow charts, equipment production and installation, technical operation training and after-sales services, to helps customers solve oil technology problems. Huatai Oil Machinery provides guarantees for the smooth production of the cooking oil plant.

All in all, to consult and purchase rice bran oil processing machine, you can go to Henan Huatai Cereals and Oils Machinery Co., Ltd. We will send you the complete fetures and specifications of the equipment. Please contact us the price for Rice Bran Oil Processing Equipment. Also, welcome to visit our factory and for latest quotation.