Rice bran oil factory equipment is the main machine to produce rice bran oil. The full set of rice bran oil factory equipment mainly includes: rice bran oil pretreatment machine, rice bran oil extraction machine and rice bran oil refinery machine. The oil residue in cake after prepressing will be about 15%, oil residue in meal after solvent extraction plant will be less than 1%. Rice bran oil refinery machine is mainly to refine the crude oil comes from prepressing machine and solvent extraction machine, after refining, the oil can meet with first grade GB standard.

Introduction of complete set of rice bran oil pretreatment and prepressing machine:

Pretreatment and prepressing section is the basic parts for a rice bran oil mill plant. This section includes: cleaning, puffing process to adjust the peanut seed into the best condition for oil pressing, easy to press oil out and easy for next production section.

Process flow chart of rice bran oil pretreatment and pressing machine:

Raw material (rice bran) → Cleaning →Conditioning → Expansion(extrusion machine) → solvent extraction plant

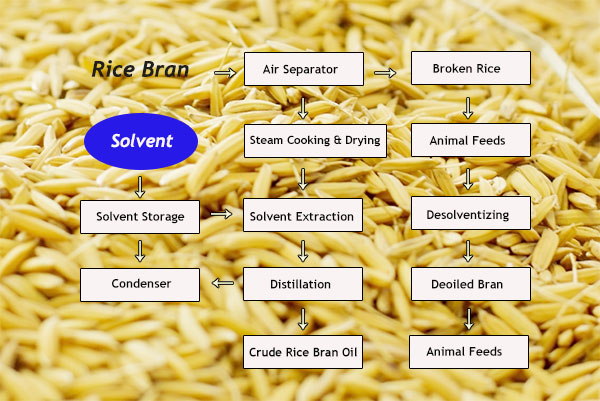

Introduction of complete set rice bran oil solvent extraction machine:

Solvent extraction section is the second part of rice bran oil mill plant. This solvent extraction section includes: extraction system, D.T.D.C system, miscella stripping system, cooling and recycle system. After this process you can get most oil out from rice bran cake.

Process flow chart of rice bran oil extraction machine:

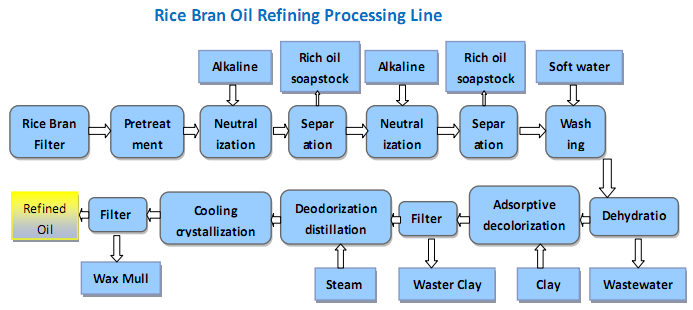

Introduction of complete set rice bran oil refinery machine:

After oil pressing process or oil solvent extraction process, we get crude rice bran oil. However, the crude rice bran oil can’t eat and sell to the market. The crude rice bran oil must be processed with rice bran oil refinery plant. Rice bran Oil Refinery Plant can remove unhealthy impurities such as phosphatides, free fatty acids (FFA), pigments, off-flavor, etc. After refining, the flavor, color and smell of rice bran oil is improved, the stability is improved which is good for long time storage, the smoke point of oil is increased.

What’s more, rice bran oil refinery can refine almost all types of oils, such as corn oil, soybean oil, peanut oil, cottonseed oil, rapeseed oil, sunflower oil, palm oil, palm kernel oil, and so on.

Refinery section is one of the most important process of Rice Bran Oil Mill Plant. This section mainly includes: Degumming, Deacidification, Decolorization and Dodorization etc. This process can remove the hazardous substances and useless dross, to get the GB standard oil.

Process flow chart of rice bran oil refinery machine:

Degumming and Deacidification Section: Rice bran oil degumming and deacidification section uses washing method to separate soap residual from mixing oil, providing preparation for next step rice bran oil refinery process.

Decolorizing Section: Rice bran oil decolorizing section is mainly used to remove oil pigment, residual soap and metal ions during rice bran oil milling process.

Deodorization Section: Rice bran oil deodorization section composes of part of crude rice bran oil mill processing equipment. It plays important part in improving oil quality after crude rice bran oil process.

Dewaxing Section: Because there is some wax in the sunflower oil, corn oil, rice bran oil, etc., if you want to get the first grade cooking oil , de-waxing machine is required. It depends on the customer.

After above steps, the final product is refined edible oil ,which can reach the level of consumption! Of course, we can produce and supply rice bran oil refinery plant with various kinds of capacity and oilseeds.

Huatai’s Professional Rice Bran Oil Factory Equipment

Henan Huatai Cereals and Oils Machinery Co., Ltd. has been committed to the production and research and development of grain and oil machinery for 37+ years. It has mature production and manufacturing processes and skilled technical workers for edible oil processing machine, and is committed to providing customers with high-quality, cost-effective cooking oil equipment, mainly includes cooking oil press machine, edible oil extraction machine, vegetable oil refining equipment, complete edible oil production lines, etc. The equipment models are complete and the quality is good. Also, we provide customized services for edible oil mills to help clients solve different product needs. Our edible oil processing machine are sold to more than a dozen countries and are well received by domestic and foreign customers.

All in all, to consult and purchase rice bran oil processing machine, you can go to Huatai Oil Machinery. Please leave your inquiry information, such as: the type of your oil seed, machine capacity (TPD, how many tons to process per day), processing technology (Pressing, extraction, refining) or full set of production lines, etc. We will contact you ASAP and send you the complete features and specifications of the equipment. Welcome to visit our factory and for latest quotation.