The 250TPD rice bran oil processing line includes rice bran pretreatment process, rice bran oil solvent extraction process and rice bran oil refining process.

Rice bran pretreatment process includes rice bran cleaning, extrusion, and drying; Rice bran oil solvent extraction process has two process methods: meal and oil: puffed bran, extraction, evaporation, and finished meal; expanded bran, extraction, mixed oil evaporation, and stripping , finished crude oil.

1. Rice Bran Pretreatment Section:

After the rice bran is separated from the bran, it enters the oil pretreatment workshop. It is first cleaned to remove impurities. The magnetic separator selects iron impurities and enters the rice bran extruder machine for puffing. Due to water content is high, the expanded rice bran needs to be dried in a flat-bed dryer and then transported to rice bran oil solvent extraction workshop via the scraper.

rice bran pretreatment process

2. Rice Bran Oil Solvent Extraction Machine:

1) Extraction and desolventizer toaster system: The expanded rice bran enters the rice bran oil solvent extraction plant and first enters the sealed auger of the extractor. After entering the rice bran oil extraction device, it is placed in different material compartments and extracted in a countercurrent extraction method. The concentration of the mixed oil extracted out after six cycles gradually decreases, and then it is extracted with a pure solvent.

At this time, there is not much oil left in rice bran and it turns into bran meal. After the bran meal is drip-dried, it is transported to the evaporator by the buried scraper conveyor. The function of the evaporator is to heat and evaporate the bran meal that contains a large amount of organic solvent after extraction to separate the meal from the solvent. The bran meal is transported to the packaging workshop, and the solvent is evaporated into gas and sent for condensation and recovery.

2) Mixed oil evaporation system: The mixed liquid after the oil in the puffed bran is extracted by the solvent in the extractor is called mixed oil. The mixed oil is sent to the mixed oil tank through the mixed oil pump, and then passes through the first evaporator and the second evaporator. After the butterfly stripping tower evaporates, the solvent in the mixed oil is basically evaporated, leaving crude rice bran oil, which is transported to the crude oil tank by the crude oil pump.

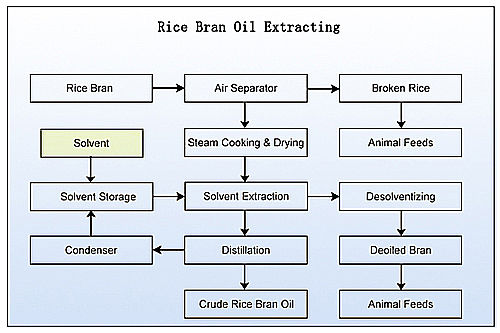

rice-bran-oil-extracting

3) Solvent recovery system: The solvent vapor in the extractor and the free gas in each container containing mixed oil are collected in the balance tank through pipelines, and then condensed and recovered through the condenser. The solvent gas evaporated by the first evaporator, the second evaporator, the butterfly stripping tower and evaporator passes through their respective condensers to condense the solvent gas into solvent for recycling and reuse. These condensers form the condensation system, which relies on circulating water for cooling, and the circulating water flows into the cooling pool. Cool naturally and reuse.

3. Rice Bran Oil Refining Plant:

1) The crude rice bran oil from the loil extraction workshop is pumped into the filter to remove residual impurities. After being heated, it is sent to the acid refining mixer. It is fully contacted and mixed with the phosphoric acid and water input from the acid metering pump to allow the colloid in the oil to separate out. Put it into a degumming centrifuge to separate out the oil-feet.

2) The oil is then pumped into the alkali refining mixer and neutralized with a certain amount of alkali solution of required concentration to precipitate the free fatty acids in crude rice bran oil, and then enters the desoap centrifuge to separate the soap stock. At the same time, the separated oil is washed with light alkali and water to wash away the residual soap in the oil, and then separated and dried by the centrifuge to obtain alkali refined oil.

3) The alkali refining oil is sent to the decolorization tower and mixed with the correctly quantified decolorized clay. After a decolorization process that requires temperature, time, and vacuum, the clay that has absorbed the colored substances and other impurities in the oil, then is filtered and separated by a filter.

4) The obtained decolorized oil is heated and degassed and sent to the deodorization tower. The oil is further heated to the deodorization temperature in the deodorization tower and deodorized by steam stripping under high vacuum. After cooling, the deodorized oil is obtained.

5) The deodorized oil is cooled and crystallized and then filtered to remove the rice bran wax. After further cooling and crystallization, the high melting point solid fat in rice bran oil is filtered to remove, then get the final first-grade refined oil.

Huatai’s Professional After-sales Service:

If you have any questions about machinery, or equipment operation for many years and you want to transform the factory, Henan Huatai will solve these problems for you. Henan Huatai Cereals And Oils Machinery Co., Ltd. always put product quality and customer interests as the first, insist on better service concept, we will provide high quality products according to promise on perfect site services and after-sales service. Specific services is as follows:

1. To provide complete sets of equipment and accessories on time.

2. Henan Huatai wiould send an engineer to the country of customer for the installation guide, training technicians and operators for the clients.

3. After-assembly Equipment. Our company will be in charge of stand-alone equipment debugging, online debugging and feeding trial run, ensure the normal operation of the equipment in full load condition.

4. Equipment Operation. If equipments have any problems or the customer want to transform and expand the scale of production, all problems you can contact us, we will provide customers the best solution.

High quality service is what we are pursuing. Our service is available all around the world. And our high quality service team is ready to provide you with fast and efficient service from the tailored solutions for competitive production process to free training of complete plant installation.

Why Choose Huatai?

1. Henan Huatai Cereals And Oils Machinery Co., Ltd. has a professional R&D team, continuous innovation, won several national patents, our professional engineer team will design a customized for you to save cost and create more benefit for you and environmental protection of the equipment as much as possible according to your requirements.

2. Our belief is “wining through fine process”. Huatai factory workshop covers an area of 100000 square meters, including manufacturing workshop area more than 21600 square meters. Our factory is equipped with a standard professional production workshop, 2 sets machining workshop and 12 sets engineering installation department, etc. Huatai machinery has all kinds of advanced production and processing equipment 120 units, including lathe, planer, milling machine, drilling machine more than 80 units, 10 sets cut sheet molding equipment, welding equipment with submerged arc automatic welding machine 6 units, dc welding machine, ac welding machine more than 80 sets, also equipped with all kinds of high quality auxiliary equipment and testing equipment. Welcome to visit our factory!

3. Henan Huatai adheres to the principle of “Perfect Delivery”, installation and debugging equipment for you, for your training operators and daily maintenance of machine and some handling daily glitches.

Certifications: