Rice bran oil plant is a facility that produces rice bran oil, which is an edible vegetable oil extracted from the outer brown layer of rice. On the one hand, rice bran oil has a high smoke point and a mild flavor, and it contains various nutrients and bioactive compounds, such as vitamin E, antioxidants, oryzanol, tocopherols, tocotrienols, and lecithin. On the other hand, rice bran oil can be used for cooking, frying, baking, salad dressing, and as an ingredient in cosmetics and pharmaceutical products. All in all, the cost of setting up a rice bran oil plant depends on many factors, such as the capacity, location, equipment, raw materials, labor, transportation, taxes, and market demand.

Generally speaking, a rice bran oil mill plant typically involves several steps, such as rice bran expand, extraction, refining, bleaching, deodorization, and packaging.

Pretreatment Process of Rice Bran Oil:

The rice bran oil pretreatment process includes the cleaning section, breaking section, flaking section, softening section and oil pressing section.

1. Create a good product environment.

2. Minimize the total fat loss, increase oil yield and output and improve the quality of oil and cake meal.

3. Comprehensively utilize impurities and offal.

4. What’s more, perfectly to match Rice Bran Oil Solvent Extraction Line, also design different production processing according to different raw materials.

Solvent Extraction Process of Rice Bran Oil:

1) Firstly, adopting negative pressure evaporation can ensure excellent oil quality;

2) Next, extraction system is highly adaptable and can adapt to different raw materials;

3) Finally, all equipment is provided with exhaust gas absorption systems with excellent absorption effect, as well as full energy saving design utilizes heat energy for many times and save steam consumption.

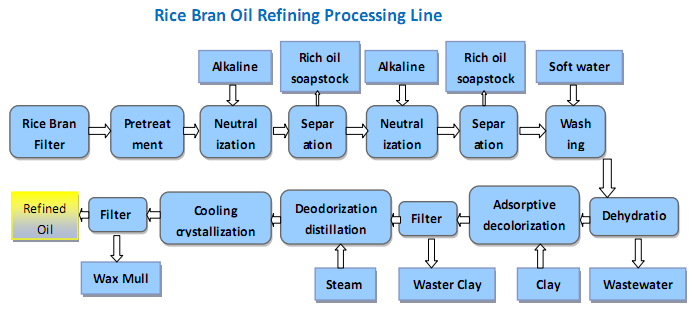

Rice Bran Oil Refinery Process:

1. Continuous alkali refining shortens contact time between oil and lye, reduces grease saponification, lowers refining consumption and improve efficiency;

2. Decolorization adopts the technology of combining premixing and steam mixing bleaching, which improves the efficiency, saves the consumption of bleaching clay, and it is simple and convenient to operate, and negative pressure state avoid oxygen in the air from contacting with hot oil, thereby ensuring oil product quality, inhibiting acid value to rise again and lowering peroxide value;

3. Deodorization adopts new type continuous deodorization equipments which is applicable for plant oil deacidification and deodorization of high acid value and low resin content, the actual production proves its most obvious advantages are strong deacidification ability, excellent hotbleaching effect, high refining rate, steam economization, good oil quality;

4. The process has multiple heat exchange, which makes full use of heatenergy system, effectively reduces steam consumption, and also has the advantages of adjustable production process.

Advantage of Huatai Rice Bran Oil Processing Machine:

(1) High oil yield, obvious economic benefit.

(2) Residual oil rate in the dry meal is low.

(3) Improving the quality of the meal and oil.

(4) Low processing cost, high labor productivity.

(5) High automatic and labor saving.

Huatai Rice Bran Oil Equipment Return on Investment (ROI) Analysis:

ROI analysis involves multiple variables. Specific figures need to be adjusted according to your actual situation (scale, location, raw material costs, etc.).

-

Investment Cost Estimation (taking 100TPD Rice Bran Oil Processing Plant as an example)

Equipment investment: Includes a complete rice bran oil production line for stabilization treatment (extrusion), pretreatment, extraction, and refining (four stages: degumming, deacidification, decolorization, and deodorization). Huatai rice bran oil equipment price is estimated to be between 3 million and 6 million RMB, depending on the degree of automation and configuration.

Factory building and infrastructure: Approximately 1 million to 2 million RMB.

Installation, commissioning, and working capital: Approximately 1 million to 1.5 million RMB.

Total investment estimate: Approximately 5 million to 9.5 million RMB.

-

Operating Costs and Revenue Analysis (annual basis, rough estimate)

Main assumptions:

300 operating days per year, processing 100 tons of rice bran per day.

Rice bran purchase price: Approximately 2,000 RMB/ton (prices fluctuate significantly).

Crude oil yield from rice bran: 14%-16% (assuming good stabilization treatment, taking the upper limit).

Crude oil refining rate: 85% (Grade 1 oil).

Rice bran meal yield: Approximately 80%, with high protein content, making it a high-quality feed.

Revenue:

Rice bran oil revenue: Annual production of Grade 1 oil is approximately 100 tons/day * 16% * 85% * 300 days ≈ 4,080 tons. The selling price of Grade 1 rice bran oil is approximately 10,000 – 12,000 RMB/ton, taking the median value of 11,000 RMB, the oil sales revenue is approximately 44.88 million RMB.

Rice bran meal revenue: Annual production of meal is approximately 100 tons/day * 80% * 300 days = 24,000 tons. The selling price is approximately 2,000 RMB/ton, so the meal sales revenue is approximately 48 million RMB. Total Revenue: Approximately 92.88 million RMB/year.

Cost Breakdown:

Raw Material Costs: 30,000 tons of rice bran * 2,000 RMB/ton = 60 million RMB.

Processing Costs (energy consumption, labor, auxiliary materials, packaging, depreciation, etc.): Approximately 800 – 1,200 RMB per ton of raw material; taking 1,000 RMB, the annual processing cost is 30 million RMB.

Total Costs: Approximately 90 million RMB/year.

Gross Profit Estimation:

Annual Gross Profit ≈ Total Revenue – Total Costs = 92.88 – 90 = Approximately 2.88 million RMB.

Note: This is a very simplified model. In reality, profits can be significantly increased through refined management, deep processing of by-products (such as gamma-oryzanol and calcium phytate), and brand premium. Meanwhile, fluctuations in rice bran and oil prices have a significant impact on profits.

-

ROI Calculation

Static Payback Period:

Annual Net Profit (assuming gross profit, before tax, etc.) ≈ 2.88 million RMB.

Taking the median total investment of 7.25 million RMB.

Static Payback Period = 7.25 / 2.88 ≈ 2.5 years.

Return on Investment (ROI):

Annual ROI = Annual Net Profit / Total Investment * 100% = 2.88 / 7.25 * 100% ≈ 39.7%.

Please note: The above calculations are highly simplified ideal models. Actual ROI is profoundly affected by the following factors:

Positive factors: Stable and controllable raw material supply chain, deep processing of by-products, branded oil sales, government subsidies for technological transformation or agricultural industrialization.

Risk factors: Drastic fluctuations in raw material prices, poor sales channels for finished oil products, fierce homogeneous competition, and unstable initial production rate and product quality.

Huatai Provides Best Rice Bran Oil Plant Cost for Your Business!

Henan Huatai Cereals and Oils Machinery Co., Ltd. has been committed to the production and research and development of grain and oil machinery for 37+ years. It has mature production and manufacturing processes and skilled technical workers for edible oil processing machine, and is committed to providing customers with high-quality, cost-effective cooking oil equipment, mainly includes cooking oil press machine, edible oil extraction machine, vegetable oil refining equipment, complete edible oil production lines, etc. The equipment models are complete and the quality is good. Also, we provide customized services for edible oil mills to help clients solve different product needs. Our edible oil processing machine are sold to more than a dozen countries and are well received by domestic and foreign customers.

All in all, to consult and purchase edible oil processing machine, you can go to Huatai Oil Machinery. Please leave your inquiry information, such as: the type of your oil seed, machine capacity (TPD, how many tons to process per day), processing technology (Pressing, extraction, refining) or full set of production lines, etc. We will contact you ASAP and send you the complete features and specifications of the equipment. Welcome to visit our factory and for latest quotation.